Cargo Survey

1. Tank Cleanliness Inspection

“Avoid Cargo Contamination – Prove Your Tanks Are Clean and Ready”

Even minor residues can ruin sensitive liquid cargoes. Our Tank Cleanliness Inspections use visual checks, solvent tests, and ATP swabs to verify tanks meet:

- Chemical cargo standards (e.g., CPP, ISO 8217).

- Oil major requirements (Shell, Chevron, etc.).

- P&I Club guidelines for contamination prevention.

Includes digital photo reports with timestamp/location tags for legal protection.

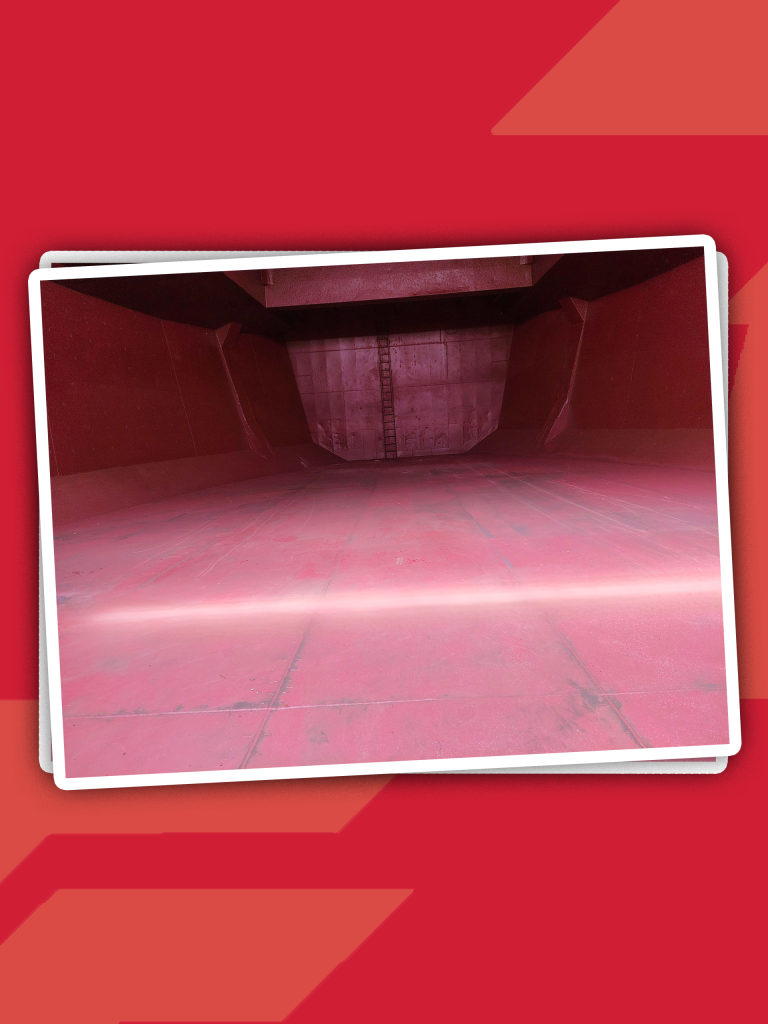

2. Cargo Hold Cleanliness/Readiness Survey

“Is Your Cargo Hold Really Ready for Bulk Cargo? Don’t Guess – Know.”

Grain, coal, and fertilizers demand spotless holds. Our surveyors:

- Check for previous cargo residues, rust, or moisture.

- Verify lining/coating integrity.

- Issue certificates accepted by charterers and insurers.

Recently prevented a $250K claim for a client loading wheat in Surabaya.

3. Ultrasonic Weathertightness Hatch Cover Test (Repeated from Vessel Surveys if needed)

“Watertight Hatch Covers = Dry Cargo = Zero Claims”

Hatch cover leaks cause millions in cargo claims annually. Our UT testing uses digital ultrasonic gauges to:

- Measure seal compression gaps.

- Identify invisible corrosion under seals.

- Generate pass/fail reports accepted by P&I Clubs.

- Identify any leak using our Class approved Ultrasonic hatch cover tester device.

It is important for you as Bulk carrier owners, charterers, cargo insurers and P&I Club.

4. Ullage/Quantity Survey (Liquid Cargo)

“Stop Disputes Over Missing Barrels – Measure Liquid Cargo Like a Pro”

Liquid cargo discrepancies cause 30% of shipping disputes. Our Ullage Surveys:

- Use calibrated sounding tapes and temperature probes.

- Calculate quantities per ASTM/API MPMS standards.

- Detect unauthorized cargo blending or theft.

Trusted by traders, terminals, and P&I Clubs for impartiality.

5. Bunker Quantity Survey (BQS)

“Bunker Disputes Cost Thousands. We Deliver Proof.”

Missing” bunkers hurt your bottom line. Our BQS:

- Checks for sludge, water content, and quality.

- Provides court-admissible reports with vessel tank diagrams.

- Measures fuel before/after delivery using MARPOL-compliant methods.

Saved a client $18K in a Singapore bunker dispute last month.

6. Lashing Survey

“Heavy Equipment on Board? Secure It Right – Avoid Costly Shifts at Sea”

Improper lashing of machinery, construction equipment, or oversized cargo risks catastrophic damage and voyage delays. Our General Cargo Lashing Surveys ensure:

- Compliance with IMO/CSM guidelines for non-containerized cargo.

- Structural integrity checks of lashing points (deck fittings, D-rings).

- Load distribution analysis to prevent deck overstressing.

- Documentation with time-stamped photos for insurance/P&I claims.

7. Cargo Loading/Discharge Supervision

“Your Cargo’s Safety Starts the Moment It’s Moved”

From fragile electronics to hazardous chemicals, we:

- Monitor loading/unloading procedures for compliance.

- Document damage in real-time (photos/video).

- Supervise ventilation, temperature, and segregation.

Prevented a $500K chemical cargo contamination in Jakarta last quarter.

Chat WhatsApp

Chat WhatsApp